With so many different ways to measure product size, it’s no wonder many businesses are unsure about which method to use. Explore some of the best ways to measure the sizes of products.

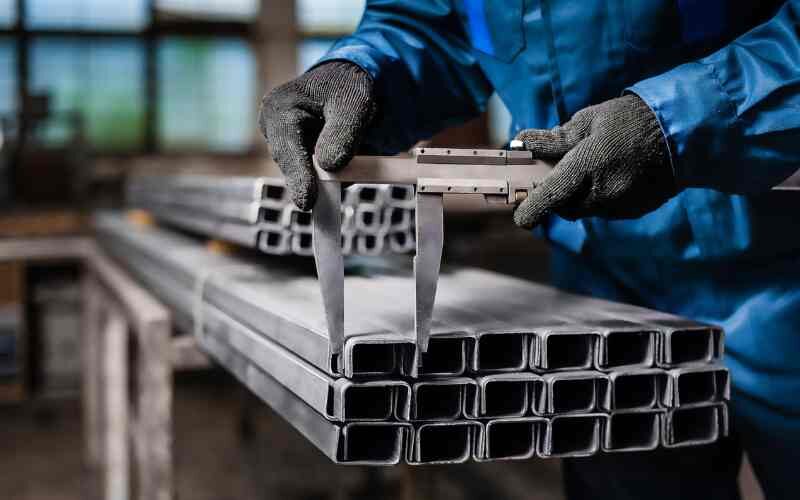

Calipers: The Classic Option

Calipers are a tried-and-true method for measuring the sizes of products. There are several types of calipers—vernier, dial, and digital—each with its own pros and cons.

Fortunately, calipers can measure external dimensions, internal dimensions, and depth with ease. These devices are versatile, easy to read, and relatively inexpensive, making them a measurement staple in many industries.

Air Gages: A Precise Alternative

The origin of the air gage is quite in-depth, but these instruments have proven time and again to be invaluable tools for measuring product sizes. By using air pressure, air gages can determine the dimensions of an object with incredible precision. This method works by forcing air through a small orifice and measuring the backpressure that results from the object being measured.

By comparing the change in air pressure to a predetermined standard, you can obtain highly accurate measurements. Air gages are particularly useful when dealing with tight tolerances and complex geometries, where traditional measuring devices may not fit or provide accurate readings.

Laser Measurement: The Future of Sizing

Laser scanning technology has made leaps and bounds in recent years and is quickly becoming a popular method for measuring the sizes of products. A laser scanner projects a beam of light onto the surface of the object, and the light is then reflected back to the scanner.

The device uses the time it takes for the light to return to calculate the object’s measurements. This method allows for whole-surface scanning, which produces a 3D model of the measured object.

With the ability to quickly and accurately measure large areas, laser scanning can be beneficial for inspecting irregular shapes, locating wear and tear on components, and performing quality control.

Vision Systems: Measurement Without Touch

Vision systems are another great way to measure the sizes of products. Instead of lasers, these systems use optical sensors and cameras to measure the sizes of products without the need for physical contact.

Once the object is placed within the camera’s field of view, the camera can capture an image that a computer processes to extract measurements. Vision systems offer speed, accuracy, and non-contact measurements, making them an ideal choice for fragile or complex parts.

Coordinate Measuring Machines (CMMs): Precision Meets Automation

Last but not least, CMMs have become an integral part of many quality control processes. These machines use highly sensitive probes to measure the sizes of products by touching the surfaces of the objects at various points.

By inputting specific program data, you can direct the machine to measure specific dimensions or run an entire part inspection. CMMs are highly accurate and can be used for both large and small parts, making them a versatile addition to any measuring arsenal.

end of post … please share it!

end of post idea for home improvement

view and analyze home improvement ideas at our LetsRenovate center

Helpful article? Leave us a quick comment below.

And please give this article a rating and/or share it within your social networks.